Magnetron Sputtering Vacuum Coating Machine

High Uniformity · Low Temperature · Large Area Coating

CGVAC Magnetron Sputtering Vacuum Coating Machine

CGVAC Magnetron Sputtering Vacuum Coating Machine utilizes advanced sputtering technology, engineered for high-quality, uniform, and durable thin film deposition.

Magnetron sputtering excels at large-area, low-temperature deposition, making it ideal for stainless steel panels, glass, electronics, and optical components requiring precise, repeatable coating performance.

How It Works (Operating Principle)

Magnetron sputtering is a physical vapor deposition (PVD) process in which charged particles bombard the target surface in a crossed electric and magnetic field. The ejected atoms from the target then condense on the substrate, forming a dense, uniform, and firmly adhered coating layer.

Advantages of CGVAC Magnetron Sputtering Vacuum Coating Machine

High Film Uniformity

Low-Temperature Deposition

Material Flexibility

Precise Process Control

Multi-Layer Film Support

Applications of Magnetron Sputtering Vacuum Coating Machine

Stainless Steel Hardware & Household Products

Electronics & Optics

Glass

Automotive Interior & Components

Custom Your Magnetron Sputtering Vacuum Coating Machine

Process & Configuration Info

| Chamber Size (Optional) | Ø800mm – Ø3000mm (customizable) |

| Power Supply | DC/Intermediate frequency power supply |

| Coating Technology | Magnetron sputtering + optional arc hybrid |

| Target Materials | Titanium (Ti), Chromium (Cr), Zirconium (Zr), Stainless Steel, ITO, FTO, and others |

| Process Gases | Argon (Ar), Nitrogen (N₂), Oxygen (O₂), H₂ (Hydrogen) |

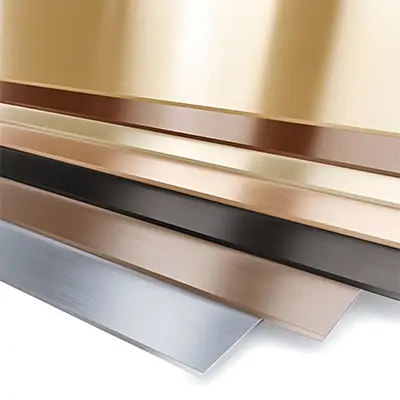

| Available Coating Colors | Gold, rose gold, black, silver, blue, champagne, matte/satin colors, and different colors. |

| Customization Options | Customized coating color, chamber size, target material/number, fixture design, and process plan |

Technical Specifications

| Item\Model | CZ1214 | CZ1416 | CZ1618 | CZ1818 | CZ2118 |

| Chamber Dimension (D×H mm) | Ø1200×H1400 | Ø1400×H1600 | Ø1600×H1800 | Ø1800×H1800 | Ø2100×H1800 |

| Ultimate Vacuum (Pa) | ≤8×10⁻⁴ | ≤8×10⁻⁴ | ≤8×10⁻⁴ | ≤8×10⁻⁴ | ≤8×10⁻⁴ |

| Pumping Time to 2×10⁻¹ Pa (min) | <5 | <5 | <5 | <5 | <5 |

| Targets (PCS) | 40 | 60 | 80 | 160 | 160 |

| Total Power (kW) | 50 | 60 | 80 | 110 | 120 |

| * Equipment specifications can be customized according to customer requirements. | |||||

Our Magnetron Sputtering Vacuum Coating Machine

Magnetron Sputtering Vacuum Coating Machine for Jewelry Beads, PVD Coating Machines

Magnetron Sputtering Vacuum Coating Machine for Ceramic Tableware, Ceramics PVD Coating Machine

Magnetron Sputtering Vacuum Coating Machine for Plastic, PVD Coating Machine China

Magnetron Sputtering Vacuum Coating Machine, Automotive Interior & Components PVD Coating Machine

PVD Coating Machine for Electronics, Magnetron Sputtering Vacuum Coating Machine Manufacturer

PVD Coating Machine for Stainless Steel Hardware, Magnetron Sputtering Vacuum Coating Machine

Glass PVD Coating Machine, Magnetron Sputtering Vacuum Coating Machine

Magnetron Sputtering Vacuum Coating Machine, Sanitary Ware PVD Coating Machine

Work With a Reliable PVD Coating Machine Manufacturer

Contact Us

FAQ

- Q: What types of materials can PVD coating machines process?

A: Sanitary ware, jewelry &beads, daily ceramics, stainless steel, glass, plastics, and electronic & optical components for both decorative and functional coatings.

- Q: Can the CGVAC PVD vacuum coating machines be customized?

A: Yes. We offer standard and fully customized solutions, including chamber size, coating process, capacity, and color etc.

- Q: Do you provide installation and training?

A: Yes. We provide global on-site installation, operator training, and remote technical support.