Whenever companies intend to launch or upgrade their PVD coating technology, one critical question is consistently raised: how to make the right choice between a マグネトロンスパッタ真空成膜装置 and a マルチアークイオン真空塗装機. Although both technologies belong to the PVD coating category, they differ significantly in coating principles, performance characteristics, and application suitability. An improper equipment selection may result in insufficient coating performance, low production efficiency, or even reinvestment at a later stage. As a プロフェッショナルPVDコーティング装置メーカー、CGVAC provides the following comparison insights based on real production experience and equipment selection practices.

Why Choosing the Right PVD Coating Machine Matters?

In real manufacturing projects, many companies focus heavily on equipment price while overlooking key factors such as application requirements, coating functionality, and long-term scalability. As a result, problems often appear after installation:

- Insufficient coating adhesion and shortened service life

- Low deposition efficiency that limits production capacity

- Narrow process adaptability, restricting future product development

Therefore, selecting a vacuum coating machine is essentially an investment in long-term production capability rather than a one-time purchase.

What Is a Magnetron Sputtering Vacuum Coating Machine?

Working Principle (Simplified)

A magnetron sputtering vacuum coating machine operates by generating a magnetic field to confine plasma within a vacuum chamber. Inert gas ions bombard the target material, ejecting atoms that deposit onto the substrate surface and form a thin film.

Key Advantages of Magnetron Sputtering

- Excellent coating uniformity for appearance-sensitive products

- High composition controllability for multi-element and functional films

- Stable and repeatable coating processes

Typical Applications

- Decorative coatings

- Optical and electronic thin films

- Functional coatings with precise thickness control

- Applications requiring high surface smoothness

For manufacturers prioritizing surface consistency and functional film accuracy, magnetron sputtering remains a proven and reliable solution.

What Is a Multi-Arc Ion Vacuum Coating Machine?

Multi-Arc Ion PVD Coating Principle

A multi-arc ion vacuum coating machine uses high-current arc discharge on cathode targets to directly vaporize the target material. The generated high-energy metal ions bombard the substrate surface, forming dense coatings with strong adhesion.

Core Advantages of Multi-Arc Ion Coating

- Superior coating adhesion for demanding environments

- High deposition efficiency for mass production

- Dense coatings suitable for thicker and more durable layers

Typical Application Fields

- Stainless steel products

- Bathroom hardware and decorative fittings

- Tableware and kitchenware

- Industrial wear-resistant and protective coatings

When products require both decorative appearance and mechanical durability, multi-arc ion PVD technology often offers clear advantages.

Magnetron Sputtering vs Multi-Arc Ion: Key Differences

| Comparison Dimension | マグネトロンスパッタ真空成膜装置 | マルチアークイオン真空塗装機 |

|---|---|---|

| Coating Mechanism | Ion sputtering under magnetic field confinement | High-energy arc evaporation with ion bombardment |

| Coating Adhesion | Moderate to high | Very high, suitable for heavy-duty applications |

| Coating Uniformity | Excellent for large-area and thin films | Good, with emphasis on coating density |

| Deposition Efficiency | Medium | High |

| Main Application Focus | Decorative and functional thin films | Wear-resistant and decorative-functional coatings |

Understanding these differences helps manufacturers avoid technology mismatches and make informed decisions.

How to Choose the Right PVD Equipment for Different Industries

Bathroom and Decorative Hardware

- High requirements for color stability, scratch resistance, and durability

- Multi-arc ion coating performs well under frequent-use conditions

- Magnetron sputtering is suitable when extreme uniformity is required

Stainless Steel Tableware and Kitchenware

- Strong emphasis on coating adhesion and corrosion resistance

- Multi-arc ion PVD technology offers stable performance on stainless steel

Functional and Industrial Coatings

- Priority on hardness, wear resistance, and service life

- Multi-arc ion vacuum coating machines are often preferred

- Magnetron sputtering systems are suitable for precision functional films

Key Factors to Consider When Selecting a PVD Vacuum Coating Machine

- Vacuum chamber size aligned with production capacity

- Target or cathode configuration flexibility

- Automation level and process repeatability

- Maintenance cost and long-term system stability

These factors often have a greater impact on ROI than the coating method alone.

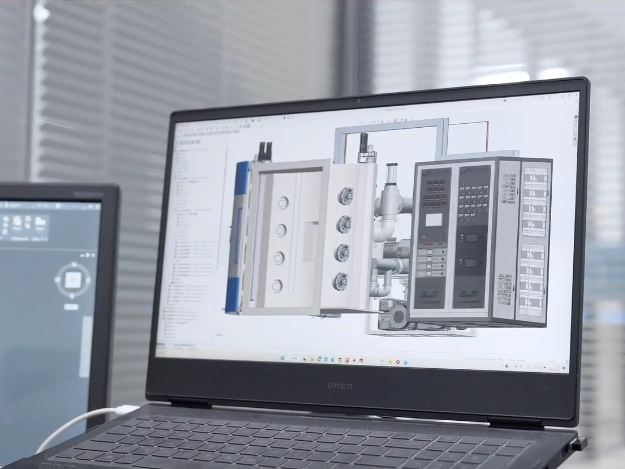

How CGVAC Supports Both PVD Coating Technologies

として reliable PVD vacuum coating machine manufacturer, CGVAC provides both マグネトロンスパッタ真空成膜装置 and Multi-Arc Ion Vacuum Coating Machines, offering customized solutions for diverse industries.

- Customized chamber structure and dimensions

- Flexible power supply and control systems

- Process optimization for stainless steel, sanitary ware, decorative parts, and functional coatings

With integrated equipment design and technical support, CGVAC helps manufacturers achieve multi-application coating capability on a single platform.

結論

Magnetron sputtering and multi-arc ion vacuum coating machines represent different strengths within PVD technology. The best choice is not the most advanced system, but the one that matches your product requirements, production goals, and market strategy. If you are planning to invest in or upgrade a PVD真空蒸着装置, consulting with experienced engineers before making a decision can significantly reduce risk. お問い合わせ today to receive a customized PVD vacuum coating machine solution for your application.