Si vous choisissez un traitement de surface pour un nouveau produit à venir, un produit qui soit durable, esthétique et qui réponde aux attentes des clients en matière de qualité supérieure, vous avez probablement déjà dressé une liste de trois options. Vous avez probablement déjà listé mentalement trois options : Revêtement PVD, galvanoplastie, et peinture. Chaque méthode promet de donner à votre produit un aspect “neuf”, mais en réalité, leurs performances, leur durée de vie et les applications appropriées varient considérablement. En tant que fabricant professionnel de machines de revêtement PVD, CGVAC compare le dépôt en phase vapeur (PVD) à la galvanoplastie et à la peinture, en expliquant le fonctionnement de chaque technologie, ses avantages et ses limites, et en expliquant pourquoi le dépôt en phase vapeur (PVD) devient de plus en plus le choix privilégié des fabricants avant-gardistes.

Comprendre les trois principales technologies de finition de surface

Revêtement sous vide PVD (Physical Vapor Deposition)

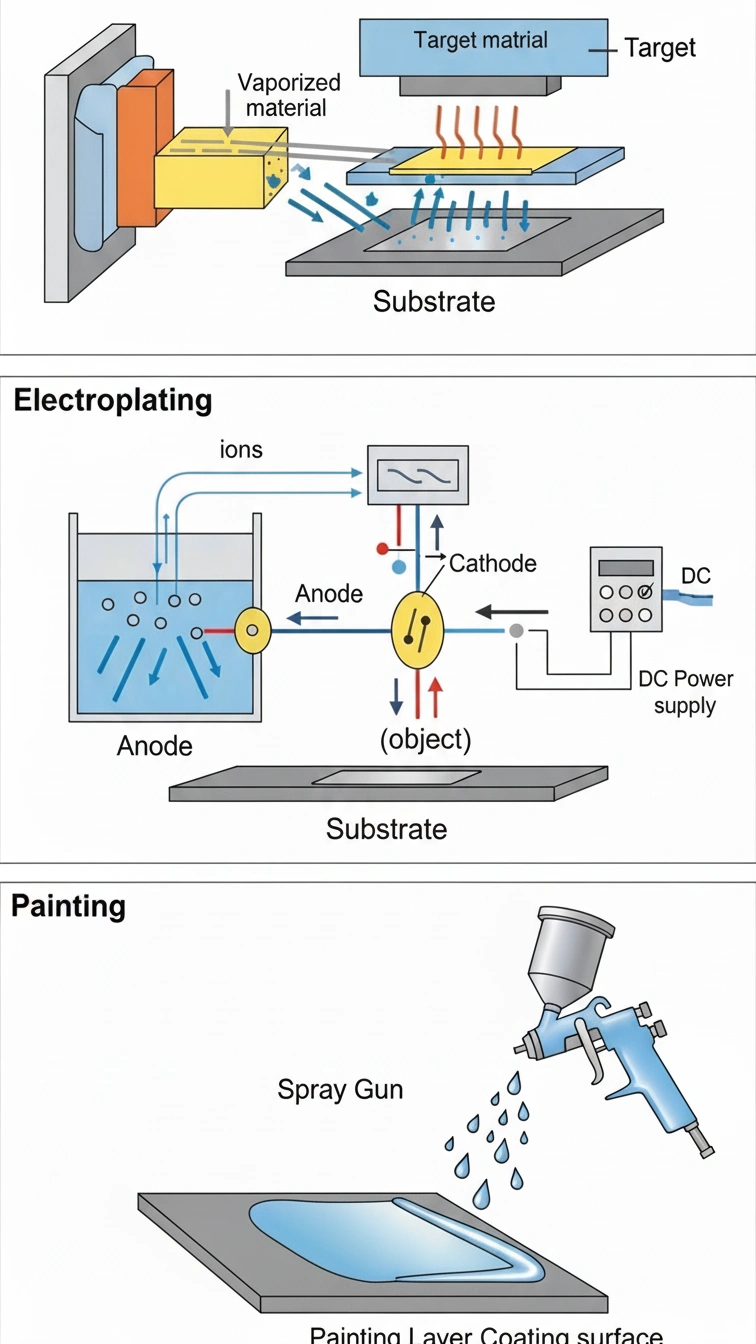

Revêtement PVD est un film mince, dense et très adhérent déposé sur divers matériaux dans le cadre d'un processus physique dans une chambre à vide. Cela implique l'évaporation ou la pulvérisation de métaux ou de céramiques sous forme de vapeur, leur transport dans le vide et leur condensation sur la surface du produit.

CGVAC propose quatre types d'équipements de revêtement PVD qui peuvent être conçus pour répondre à n'importe quel besoin industriel :

- Machine d'enduction sous vide ionique multi-arcs: taux de dépôt élevé, idéal pour les articles sanitaires, les plastiques et les bijoux.

- Machine de revêtement sous vide par pulvérisation magnétronLe système de contrôle de l'épaisseur du film : contrôle avec précision l'épaisseur du film, appliqué à l'acier inoxydable, à la robinetterie sanitaire et aux pièces décoratives.

- Machine d'enduction sous vide par évaporationLes produits de ce type sont adaptés aux céramiques, aux composants électriques et aux finitions décoratives lisses.

- Machine de revêtement PVD fonctionnelleL'utilisation d'un film de protection contre les empreintes digitales, d'un film antireflet, d'un film résistant à l'usure ou d'un film optique fonctionnel est possible.

La technologie PVD est largement appliquée articles sanitaires, produits en acier inoxydable, bijoux et perles, céramique à usage quotidien, produits en verre, composants en plastique, et électronique.

Placage électrolytique

Placage électrolytique est un procédé électrochimique qui permet d'obtenir un dépôt de métal à partir d'une solution sur la surface du produit. Il est largement utilisé en raison de son coût initial relativement faible et de ses vitesses de production rapides. Cependant, la galvanoplastie nécessite des bains chimiques contenant des métaux lourds et génère des eaux usées dangereuses pour l'environnement. L'adhérence et la résistance à la corrosion sont généralement inférieures à celles des revêtements PVD.

Peinture (revêtement par pulvérisation)

Peinture consiste à appliquer un revêtement liquide atomisé sur la surface du produit, principalement pour la décoration des couleurs. Souple et peu coûteux, il est couramment utilisé pour les plastiques, les ustensiles ménagers, les meubles et les biens de consommation. Les revêtements par peinture sont généralement les moins durables : ils ont tendance à s'écailler, à se rayer ou à se décolorer, et les émissions de COV les rendent moins respectueux de l'environnement.

Comparaison des performances : PVD vs galvanoplastie vs peinture

| Fonctionnalité | Revêtement PVD | Placage électrolytique | Peinture / Revêtement par pulvérisation |

|---|---|---|---|

| Adhésion et durabilité | Liaison moléculaire forte, excellente résistance aux rayures et à l'usure | Modéré - peut s'écailler ou se corroder avec le temps | Faible - sujet aux rayures, à l'écaillage et à l'abrasion |

| Cohérence esthétique et chromatique | Couleurs métalliques de qualité supérieure (or, or rose, noir, arc-en-ciel), finition uniforme | Couleurs métalliques limitées, moins homogènes | Nombreuses options de couleurs, mais peu d'effets métallisés ou brillants |

| Impact sur l'environnement | Respectueux de l'environnement, sans produits chimiques, conforme aux normes environnementales mondiales | Génère des eaux usées à base de métaux lourds, exigeant une conformité stricte | Émissions de COV, nécessité d'une ventilation et d'un contrôle des odeurs |

| Coût et efficacité | Investissement initial plus élevé, faible coût d'exploitation à long terme, faible taux de rejet | Faible coût initial, augmentation des coûts de mise en conformité | Faible coût de l'équipement, les retouches fréquentes augmentent le coût total |

| Épaisseur et uniformité du film | Mince, uniforme, contrôlable, même sur des formes complexes | Plus épais mais moins uniforme, risque de dépôt inégal | Épaisseur variable, dépendante de l'opérateur, moins cohérente |

Pourquoi de plus en plus de fabricants choisissent-ils le revêtement PVD ?

Le revêtement PVD n'est pas seulement une solution décorative, mais aussi une technologie transformatrice d'amélioration de la surface. Ses principaux avantages sont les suivants

Qualité de film supérieure

Les revêtements PVD offrent une excellente dureté, une résistance à la corrosion et une uniformité des couleurs, ce qui est idéal pour les produits haut de gamme exigeant une qualité stable.

Conforme aux réglementations environnementales mondiales

Le procédé PVD est respectueux de l'environnement, ne contient pas de produits chimiques et est conforme aux normes environnementales internationales. Les usines qui utilisent des équipements de revêtement sous vide PVD bénéficient d'avantages concurrentiels lorsqu'elles exportent vers l'Europe, l'Amérique du Nord et l'Asie du Sud-Est.

Soutenir les tendances futures de la fabrication

Des secteurs tels que les appareils sanitaires, la bijouterie, l'électronique et la quincaillerie domestique sont en train de passer du placage traditionnel aux technologies de revêtement sous vide. Une adoption précoce permet aux fabricants de se positionner sur des marchés à forte valeur ajoutée.

Compatible avec de nombreux matériaux

Qu'il s'agisse d'articles sanitaires, de bijoux, d'acier inoxydable, de céramique, de verre, de plastique ou d'électronique, les revêtements PVD offrent des performances supérieures et des finitions plus attrayantes que la galvanoplastie ou la peinture.

S'aligne sur l'automatisation industrielle et le contrôle des coûts

Machines de revêtement PVD CGVAC sont conçus pour une production stable, continue et automatisée, ce qui permet de réduire les coûts de main-d'œuvre et d'améliorer les taux de rendement.

Pourquoi choisir CGVAC comme fabricant de machines de revêtement PVD ?

En tant que fabricant professionnel de machines de revêtement PVD, Nous aidons les clients du monde entier à obtenir des résultats précis en matière de revêtement et à réaliser un déploiement efficace au niveau de l'usine.

- Série complète d'équipements de dépôt de couches minces par procédé physique en phase vapeur (PVD)Machines de revêtement : machines à arc multiple, à pulvérisation magnétron, à évaporation et à revêtement fonctionnel.

- Expertise dans le revêtement de l'acier inoxydable, des articles sanitaires, de la bijouterie, de la céramique, du verre et de l'électronique

- Solutions personnalisées de revêtement PVD adaptés à l'échelle de production, aux couleurs cibles, aux exigences de décoration et aux exigences fonctionnelles

- Installation à l'échelle mondiale, formation à l'utilisation et assistance après-vente

- Un équipement industriel fiable, conçu pour un fonctionnement stable à long terme

CGVAC aide les fabricants à passer de la galvanoplastie et de la peinture traditionnelles à des solutions de revêtement PVD modernes, respectueuses de l'environnement et très performantes.

Conclusion

Le revêtement PVD, la galvanoplastie et la peinture répondent chacun à des besoins différents. Revêtement sous vide PVD est devenu le choix le plus avancé, le plus durable et le plus respectueux de l'environnement pour les fabricants du monde entier. Avec La gamme complète de machines de revêtement PVD de CGVAC, Grâce au revêtement PVD, les entreprises peuvent améliorer les performances de leurs produits, en rehausser l'apparence et renforcer leur compétitivité sur les marchés mondiaux. Si vous envisagez de moderniser votre technologie de finition de surface ou de recourir au revêtement PVD pour vos lignes de production, nous contacter aujourd'hui pour solutions personnalisées pour les machines de revêtement PVD et un devis professionnel.