PVD Coating Machine for Stainless Steel, Functional Vacuum Coating Machine Manufacturers in China

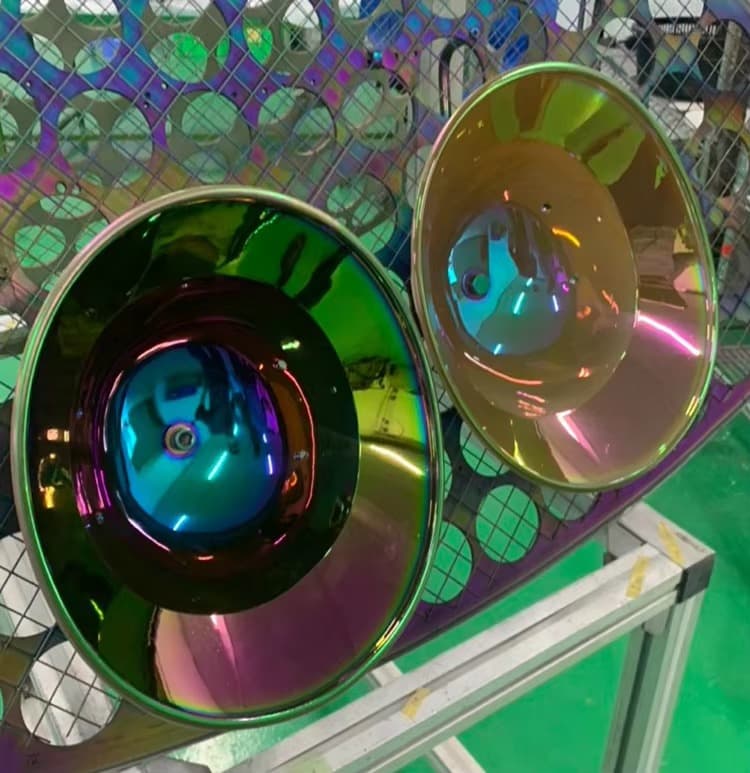

CGVAC PVD coating machine for stainless steel offers customizable, multi-technology coatings, combining aesthetics, durability, and functional performance. We provide functional PVD coating machine OEM/ODM services across diverse industries. Contact us to get a custom coating machine!

Technical Parameters:

| Target Materials | Titanium (Ti), Chromium (Cr), DLC / Carbon Targets, TiAl / TiSiN, Chromium Nitride / Titanium Nitride Systems |

| Industrial Gases | Argon (Ar), Nitrogen (N₂), Oxygen (O₂), C₂H₂/CH₄, Special Gas Mixes |

| Coating Technology | Magnetron Sputtering, Arc Ion, E-Beam Evaporation, CVD |

| Coating Systems |

DLC, TCO, anti-fingerprint films |

| Core Components | Arc target, control system, pump |

| Application | Electronics & optics, stainless steel, glass, plastics, ceramic |

| Customization | Customized size, target material, color, fixture design, and process plan |

| Service | Mechanical/sample test reports, video outgoing-inspection, and technical guidance. |

Product Detail

Specifications of PVD Coating Machine for Stainless Steel:

| Model Number | Dimension D*H (mm) | Ultimate Vacuum (Pa) | Pumping Time (Min) |

| FC1214 | 1200*1400mm | <8×10⁻⁴ | <5 |

| FC1416 | 1400*1600mm | <8×10⁻⁴ | <5 |

| FC1618 | 1600*1800mm | <8×10⁻⁴ | <5 |

| FC1818 | 1800*1800mm | <8×10⁻⁴ | <5 |

| FC2018 | 2000*1800mm | <8×10⁻⁴ | <5 |

*Equipment specifications can be customized according to customer requirements.

Features of PVD Coating Machine for Stainless Steel:

Multi-technology Composite Coating: Supports the combined use of multiple PVD coating technologies, such as multi-arc ion plating, magnetron sputtering, and evaporation deposition. Functional and decorative films can be superimposed in a single processing cycle, meeting multiple requirements such as wear resistance, corrosion resistance, and high-temperature resistance.

High-Precision Mechanical Control: A precision vacuum chamber and temperature control system ensure stainless steel products’ coating uniformity and stability. The automated control system supports mass production and small-batch, diversified process switching.

Full Material Compatibility: Designed specifically for stainless steel and other metal materials, while also adaptable to composite materials and alloys. Enables flexible combinations of various colors and functional films.

High Efficiency and Energy-Saving Design: Rapid deposition and a high-utilization power system reduce production cycles and energy consumption. Efficient gas circulation and target utilization technology reduce material waste.

Easy Maintenance: Modular component design facilitates maintenance and allows for quick target replacement or coating solution upgrades. The compact equipment structure supports long-term continuous production, ensuring stable output.

Multi-Application PVD Coating Solutions: Suitable for various industries, including kitchenware, bathroom fixtures, decorative building materials, hardware tools, electronic housings, and jewelry. The coating combination can be customized according to customer needs to achieve diversified applications that combine decoration and functionality.

Applications of PVD Coating Machine for Stainless SteeL

Why Choose CGVAC, Professional PVD Vacuum Coating Machine Manufacturer

High Production Efficiency

Excellent Film Quality

Intelligent Automation

IndepFull-System In-House R&D

Customization Support

Technical Service

Related Products

Contact Us

FAQ

- Q: What types of materials can PVD coating machines process?

A: Sanitary ware, jewelry &beads, daily ceramics, stainless steel, glass, plastics, and electronic & optical components for both decorative and functional coatings.

- Q: Can the CGVAC PVD vacuum coating machines be customized?

A: Yes. We offer standard and fully customized solutions, including chamber size, coating process, capacity, and color etc.

- Q: Do you provide installation and training?

A: Yes. We provide global on-site installation, operator training, and remote technical support.