PVD Coating Machine for Jewelry Evaporation Vacuum Coating Machine Manufacturer CGVAC

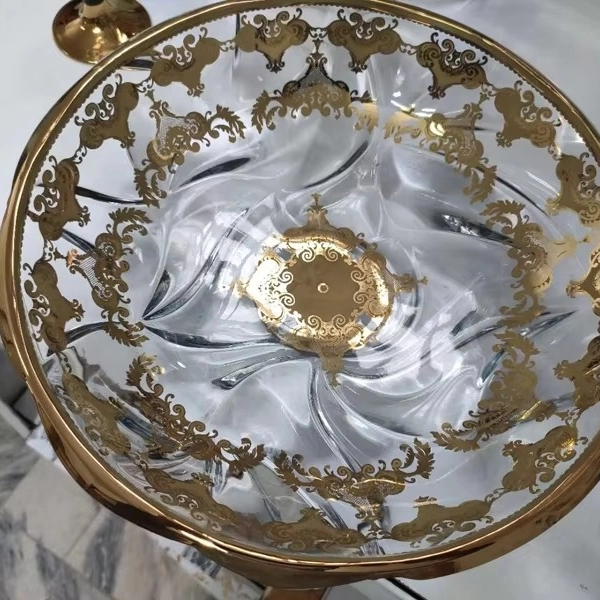

CGVAC PVD coating machine for jewelry with high-stability magnetron sputtering, multi-axis fixtures for complex shapes, and modular targets for decorative & functional finishes. Ideal for jewelry, stainless steel, glass, and multi-industry coating. Inquire now for customized coating solutions.

Technical Parameters:

| Target Materials | Al Wire, Cu, Ag, Cr (thermal), Decorative Metals |

| Coating Technology | Evaporation vacuum coating |

| Functional & Optical Films | Mainly for decorative coatings, it can be integrated with UV coating or spray layers. |

| Core Components | Arc target, control system, pump |

| Application | Plastics, daily ceramics, glass, jewelry & beads, stainless steel |

| Customization | Customized size, target material, color, fixture design, and process plan |

| Service | Mechanical/sample test reports, video outgoing-inspection, and technical guidance. |

Product Detail

Specifications of PVD Coating Machine for Jewelry:

| Model Number | Dimension DxH (mm) | Ultimate Vacuum (Pa) | Pumping Time (Min) | Total Power (kW) |

| ZZ1214 | 1200*1400mm | ≤8×10⁻⁴ | <5 | 35 |

| ZZ1416 | 1400*1600mm | ≤8×10⁻⁴ | <5 | 65 |

| ZZ1618 | 1600*1800mm | ≤8×10⁻⁴ | <5 | 75 |

| ZZ1820 | 1800*2000mm | ≤8×10⁻⁴ | <5 | 90 |

| ZZ2020 | 2000*2000mm | ≤8×10⁻⁴ | <5 | 105 |

*Equipment specifications can be customized according to customer requirements.

Features of PVD Coating Machine for Jewelry:

High-Stability Magnetron Sputtering Chamber: CGVAC’s jewelry magnetron sputtering PVD systems feature a robust vacuum chamber with precision-welded construction. This mechanical stability minimizes vibration and thermal deformation during operation, ensuring uniform coating thickness, consistent color, and repeatable quality for high-end jewelry applications.

Multi-Station Rotating Fixtures: Equipped with multi-axis rotation and versatile fixturing, the system accommodates rings, necklaces, pendants, and earrings. The mechanical design ensures full-angle coverage during sputtering, enhancing coating adhesion and edge coverage, and reducing rework for intricate decorative pieces.

Modular Target Configuration: With a flexible multi-target magnetron design, the equipment can accommodate Ti, Cr, Zr, stainless steel, and other materials. This enables a wide range of decorative finishes such as gold, rose gold, black, and gunmetal. One machine can support multiple coating styles, maximizing ROI for jewelry manufacturers.

Efficient Vacuum and Drive Systems: CGVAC PVD systems integrate high-performance vacuum pumping and stable mechanical drive systems, allowing rapid pump-down and reliable continuous operation. Even under heavy load production, the system maintains precise process control, balancing productivity with jewelry-grade surface quality—ideal for OEM, ODM, or large-scale production.

Multi-Industry Platform Offering Turnkey Coating Solutions: Built on a modular mechanical platform, CGVAC sputtering equipment is suitable not only for jewelry but also for bathroom hardware, stainless steel, glass, ceramics, and plastic decoration applications. CGVAC provides a complete solution—from equipment selection and process configuration to application deployment—enabling versatile, scalable, and multi-industry coating capabilities.

Custom PVD Coating Machine for Jewelry

Why Choose CGVAC, Professional PVD Vacuum Coating Machine Manufacturer

High Production Efficiency

Excellent Film Quality

Intelligent Automation

IndepFull-System In-House R&D

Customization Support

Technical Service

Related Products

Contact Us

FAQ

- Q: What types of materials can PVD coating machines process?

A: Sanitary ware, jewelry &beads, daily ceramics, stainless steel, glass, plastics, and electronic & optical components for both decorative and functional coatings.

- Q: Can the CGVAC PVD vacuum coating machines be customized?

A: Yes. We offer standard and fully customized solutions, including chamber size, coating process, capacity, and color etc.

- Q: Do you provide installation and training?

A: Yes. We provide global on-site installation, operator training, and remote technical support.