PVD Coating Machine for Ceramics Tableware Pottery, Multi-Arc Ion Vacuum Coating Machine Manufacturer CGVAC

CGVAC PVD Coating Machine for Ceramics with multi-arc ion PVD vacuum coating technology delivers high-precision, multi-layer coatings for tableware, pottery, and decorative ceramics. CGVAC provides custom machine solutions and technical support to help you build a coating production line. Contact us for customized coating solutions!

Technical Parameters:

| Target Materials | Titanium (Ti), Chromium (Cr), Zirconium (Zr), TiAl, Ni, Cu, Al, Fe, etc |

| Industrial gases | Argon (Ar), Nitrogen (N₂), Acetylene (C₂H₂), Oxygen (O₂) |

| Coating Technology | Multi-arc ion vacuum coating |

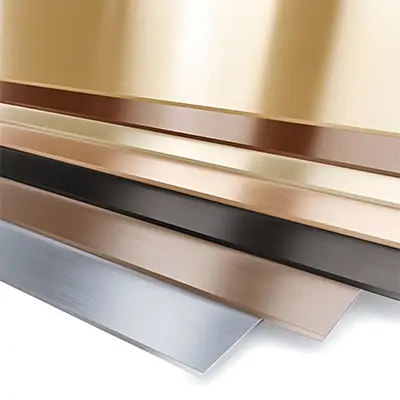

| Coating Color | Titanium silver, gold, rose gold, purple, sapphire blue, pearl, amber, deep gray, chrome black, and multicolor |

| Functional Coatings | TiN, TiCN, CrN, ZrN, TiAlN, CrAlN, DLC and other hard & wear-resistant coatings. |

| Core Components | Arc target, control system, pump |

| Application | Stainless steel, metal, sanitary ware, ceramic tableware, jewelry, glass, tile |

| Customization | Customized size, target material, color, fixture design, and process plan |

| Service | Mechanical/sample test reports, video outgoing-inspection, and technical guidance. |

Product Detail

Specifications of PVD Coating Machine for Ceramics:

| Model Number | Dimension DxH (mm) | Ultimate Vacuum (Pa) | Pumping Time (Min) | Targets (PCS) | Total Power (KW) |

| DZ1214 | 1200*1400mm | ≤8×10⁻⁴ | <5 | 10 | 50 |

| DZ1416 | 1400*1600mm | ≤8×10⁻⁴ | <5 | 14 | 60 |

| DZ1618 | 1600*1800mm | ≤8×10⁻⁴ | <5 | 21 | 80 |

| DZ1818 | 1800*1800mm | ≤8×10⁻⁴ | <5 | 28 | 110 |

| DZ2118 | 2100x1800mm | ≤8×10⁻⁴ | <5 | 32 | 120 |

*Equipment specifications can be customized according to customer requirements, Height or depth can range from 600mm to 10000mm.

Feature of PVD Coating Machine for Ceramics:

Optimized Coating Process for Ceramic Products: The unique multi-arc ion source is compatible with ceramics, terracotta, glazes, and all kinds of tableware materials. The coating is uniform and has strong adhesion, effectively improving the wear resistance and scratch resistance along with decorative properties on the surface of ceramic items.

High-precision Coating System: It retains precision in temperature control and the vacuum chamber design, enabling customized process parameters for different ceramic glazes and substrates. Such precision provides stable coatings at high temperatures without cracking or deformation.

Multi-functional Coating Options: With flexible adjustment of film thickness, color, and performance, functional, decorative, and wear-resistant films can be laid to meet the aesthetic and performance needs for ceramic products.

High Capacity and Stable Operation: The automated control system supports mass production to improve efficiency. Highly durable equipment construction allows continuous operation over a long period and ensures the stability of the production line.

Eco-Friendly and Energy-Saving Design: Optimized design in vacuum circulation and high target utilization reduces material consumption. High-efficiency energy consumption control meets the requirements for modern green manufacturing.

Multi-industry and Multi-application Solutions: It applies to tableware, ceramic crafts, ceramic gifts, decorative porcelain, art ceramics, and many other products.

Customized coating combinations: From functionality, such as scratch resistance, corrosion resistance, and wear resistance, to aesthetics like metallic luster and rich colors, CGVAC provides limitless solutions.

Applications of PVD Coating Machine for Ceramics

Why Choose CGVAC, Professional PVD Vacuum Coating Machine Manufacturer

High Production Efficiency

Excellent Film Quality

Intelligent Automation

IndepFull-System In-House R&D

Customization Support

Technical Service

Related Products

Contact Us

FAQ

- Q: What types of materials can PVD coating machines process?

A: Sanitary ware, jewelry &beads, daily ceramics, stainless steel, glass, plastics, and electronic & optical components for both decorative and functional coatings.

- Q: Can the CGVAC PVD vacuum coating machines be customized?

A: Yes. We offer standard and fully customized solutions, including chamber size, coating process, capacity, and color etc.

- Q: Do you provide installation and training?

A: Yes. We provide global on-site installation, operator training, and remote technical support.