Plastic PVD Coating Machine CGVAC Functional PVD Coating Machine Manufacturer in China

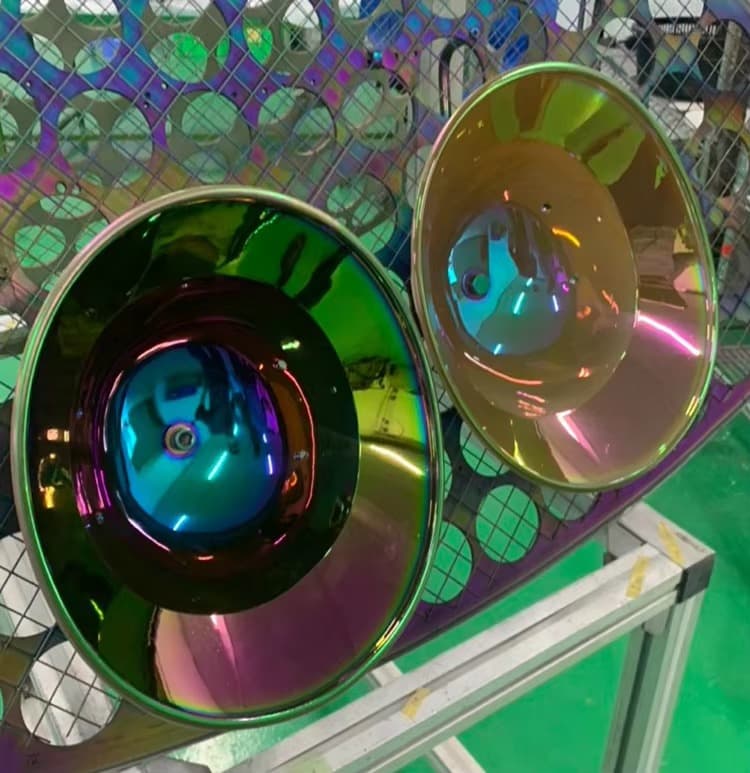

CGVAC Plastic PVD coating machine with low-temperature system, strong adhesion process, and multi-functional coatings. It can achieve high-efficiency, uniform and functional plastic coating. Custom solutions and full technical support, contact us to get a high-quality plastic coating solution now!

Technical Parameters:

| Target Materials | Titanium (Ti), Chromium (Cr), DLC / Carbon Targets, TiAl / TiSiN, Chromium Nitride / Titanium Nitride Systems |

| Industrial Gases | Argon (Ar), Nitrogen (N₂), Oxygen (O₂), C₂H₂/CH₄, Special Gas Mixes |

| Coating Technology | Magnetron Sputtering, Arc Ion, E-Beam Evaporation, CVD |

| Coating Systems |

DLC, TCO, anti-fingerprint films |

| Core Components | Arc target, control system, pump |

| Application | Electronics & optics, stainless steel, glass, plastics, ceramic |

| Customization | Customized size, target material, color, fixture design, and process plan |

| Service | Mechanical/sample test reports, video outgoing-inspection, and technical guidance. |

Product Detail

Specifications of Plastic PVD Coating Machine:

| Model Number | Dimension D*H (mm) | Ultimate Vacuum (Pa) | Pumping Time (Min) |

| FC1214 | 1200*1400mm | <8×10⁻⁴ | <5 |

| FC1416 | 1400*1600mm | <8×10⁻⁴ | <5 |

| FC1618 | 1600*1800mm | <8×10⁻⁴ | <5 |

| FC1818 | 1800*1800mm | <8×10⁻⁴ | <5 |

| FC2018 | 2000*1800mm | <8×10⁻⁴ | <5 |

*Equipment specifications can be customized according to customer requirements.

Features of Plastic PVD Coating Machine:

Low-Temperature Coating System: Utilizing CGVAC’s independently developed low-temperature evaporation and precise temperature control chamber technology, this system effectively avoids deformation, warping, and surface damage to plastics such as ABS, PC, PP, and PMMA during the coating process, ensuring batch stability and high yield.

Enhanced Adhesion: Combining plasma surface activation, ionization-assisted coating, and a metal transition layer process, this system significantly improves film adhesion, making functional coatings more wear-resistant, scratch-resistant, and sweat-resistant, ideal for high-standard industries such as electronic casings, automotive trim, and cosmetic packaging.

Multi-Process Compatibility: Supports various functional and decorative film layers on plastic surfaces, including scratch-resistant hardening films, AF anti-fingerprint films, EMI shielding/conductive films, wear-resistant metal films, and color decorative films. One machine meets the full range of needs of manufacturers of multiple types of plastic products.

Customizable Structure: CGVAC can be configured with multi-station chambers, rotating hangers, multi-layer fixture structures, and automatic feeding systems according to factory scale. This enables high-capacity, continuous, and stable production, suitable for large-volume order delivery for B2B customers. Long-term technical support: We provide one-stop service, including full-process training, mass production debugging support, overseas remote diagnostics and on-site service, and stable spare parts supply, helping customers quickly establish replicable, scalable, and highly stable plastic PVD coating production lines.

Applications of Plastic PVD Coating Machine

Why Choose CGVAC, Professional PVD Vacuum Coating Machine Manufacturer

High Production Efficiency

Excellent Film Quality

Intelligent Automation

IndepFull-System In-House R&D

Customization Support

Technical Service

Related Products

Contact Us

FAQ

- Q: What types of materials can PVD coating machines process?

A: Sanitary ware, jewelry &beads, daily ceramics, stainless steel, glass, plastics, and electronic & optical components for both decorative and functional coatings.

- Q: Can the CGVAC PVD vacuum coating machines be customized?

A: Yes. We offer standard and fully customized solutions, including chamber size, coating process, capacity, and color etc.

- Q: Do you provide installation and training?

A: Yes. We provide global on-site installation, operator training, and remote technical support.