With the ever-increasing demands for product surface quality and performance in modern manufacturing, PVD coating technology has become a crucial means of enhancing product added value. In particular, evaporation vacuum coating technology, with its high efficiency, high uniformity, and decorative properties, is widely used in various industries. However, different companies have different production needs, process requirements, and material types, making standardized equipment often insufficient to meet complex customized needs. As a professional PVD coating machine manufacturer, CGVAC helps companies achieve efficient, stable, and high-quality production goals with a comprehensive custom evaporation vacuum coating machine. We will comprehensively introduce the core advantages and industry applications of evaporation vacuum coating technology and customized equipment to assist companies in their selection process.

Overview of Evaporation Vacuum Coating Technology

Evaporation vacuum coating is an advanced thin film deposition technology. Its core principle is to heat and evaporate the material to be coated, forming a gaseous material under high vacuum, which is then deposited onto the substrate surface to form a uniform thin film. Compared to other coating technologies, evaporation coating offers the following advantages:

- High efficiency and high uniformity: Fast material evaporation allows for uniform coating on large-area substrates.

- Wide material applicability: Suitable for coating various materials, including metals, alloys, oxides, and transparent conductive films.

- Diverse functional coatings: Supports various functional requirements such as anti-reflective, anti-fingerprint, scratch-resistant, and decorative coatings.

- Low contamination and high purity: Operating in a high vacuum environment, material oxidation and impurity contamination are extremely low during the coating process.

This technology has been widely applied in plastics, ceramics, glass products, and high-end decorative materials, becoming an indispensable type of equipment in modern manufacturing.

Core Advantages of Custom Evaporation Vacuum Coating Machine

CGVAC’s custom evaporation vacuum coating machine not only features standardized functions but also offers customized design solutions to ensure a high degree of matching between the equipment and the customer’s production needs. The main advantages of customized equipment are as follows:

Multi-arc Evaporation System

- Supports large-area, high-efficiency coating, enabling multi-layer coating processes.

- CGVAC can flexibly configure the number and location of evaporation sources according to customer needs, improving production capacity and product consistency.

- Even with complex process requirements, such as multi-layer functional coatings, high-precision coating results can still be guaranteed.

Automated Control System

- Precise control of vacuum level, evaporation temperature, and film thickness ensures stable and reliable production.

- Automated monitoring reduces human error and lowers production costs.

- Supports both batch and continuous production modes, improving enterprise production efficiency.

Functional Coating Support

- Customizable anti-reflective, anti-fingerprint, scratch-resistant, and other functional coating processes are available.

- Meets the specific requirements of different industries, such as the stringent reflectivity control requirements of electronic optical products and the wear resistance and decorative needs of bathroom hardware.

- Customized functional coatings enhance product added value and market competitiveness.

Modular and Flexible Design

- Modular equipment structure allows for flexible configuration based on production scale, product type, and process complexity.

- Facilitates subsequent upgrades and maintenance, extending equipment lifespan and ROI.

- Provides scalable production line solutions, enabling multi-process combinations and automated production.

Main Industry Applications of the CGVAC Custom Evaporation Vacuum Coating Machine

Plastics Industry

Evaporation vacuum coating machine can achieve high-gloss, uniform metallic decorative layers on plastic products such as perfume bottle caps, toys, and electronic casings.

Glass Decoration and Functional Applications

Glass products (display glass, decorative panels, mirrored glass) can achieve mirror reflection, colored decorations, or special functional coatings, increasing visual appeal and product added value.

Ceramic Coating

Ceramic products, such as tableware and craft accessories, can exhibit a metallic luster or special decorative effects after surface coating, while simultaneously improving wear and stain resistance.

Jewelry and Decorative Components

Jewelry accessories and decorative metal parts often require surface coatings with high gloss and high color stability. Vacuum evaporation coating technology improves color richness and film adhesion, suitable for gold and silver plating applications.

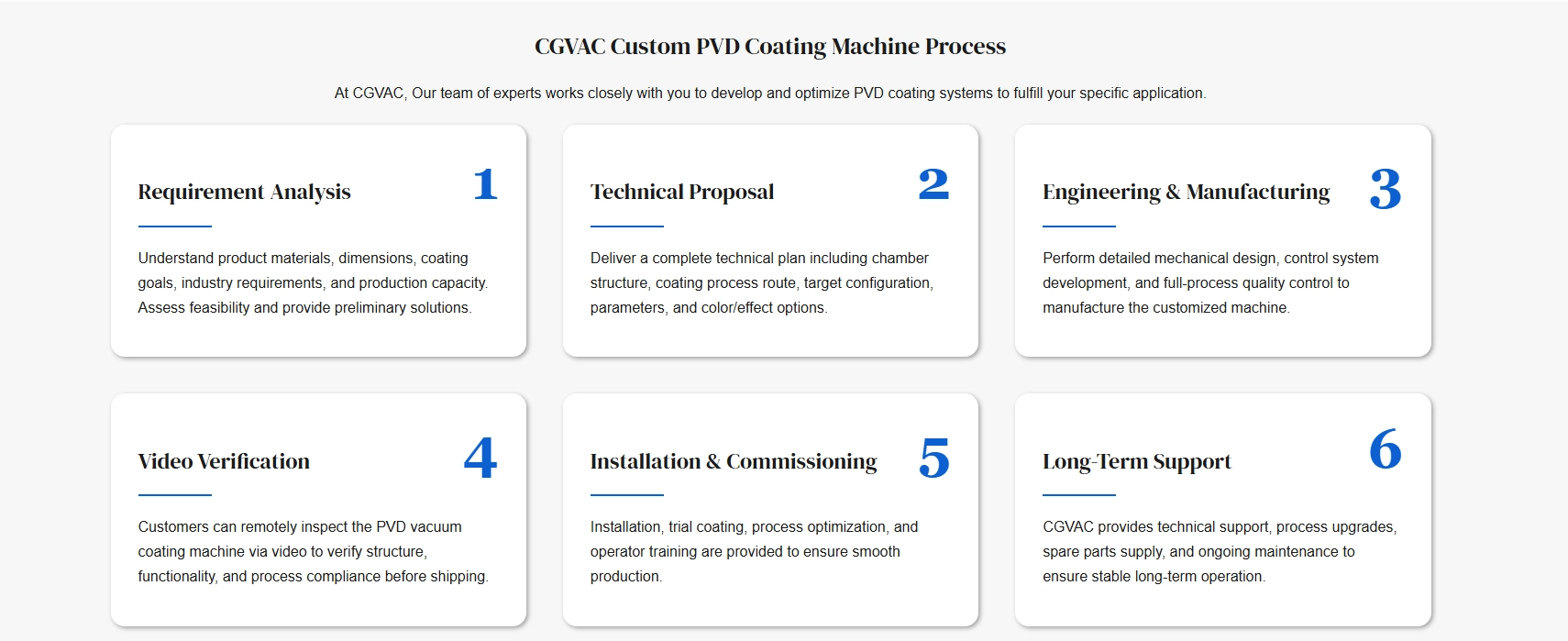

CGVAC Custom Evaporation Vacuum Coating Machine Process

Step 1: Requirements Communication and Analysis

- Detailed analysis based on the customer’s production process, material type, and production volume requirements.

- Providing feasibility studies and equipment design suggestions to ensure process requirements are met.

Step 2: Equipment Design and Manufacturing

- Customized design of multi-arc evaporation, functional coatings, and automation systems.

- Strict quality control to ensure equipment stability and lifespan.

Step 3: Installation, Commissioning, and Training

- Providing on-site installation, commissioning, and operation training services.

- Ensuring the equipment reaches a stable production state immediately after commissioning.

Step 4: Training and Support

- Providing equipment maintenance, technical upgrades, and rapid response services.

- Establishing long-term partnerships to help customers continuously optimize their production processes.

Conclusion

Vacuum evaporation coating technology, as a highly efficient, environmentally friendly, and flexible surface treatment method, is suitable for numerous industries, including plastics, glass, ceramics, and jewelry decoration.

As a professional PVD coating machine manufacturer in China, CGVAC boasts over 30 years of experience in R&D and manufacturing. With a custom evaporation vacuum coating machine, combined with high-quality evaporation systems, automated control, functional coatings, and modular design, CGVAC provides efficient, stable production solutions for customers across various industries. Contact us today to explore professional evaporation vacuum coating equipment tailored to your production line, helping your business stand out in the fierce market competition.