Evaporation Vacuum Coating Machine, Stainless Steel PVD Coating Machine Custom

The CGVAC evaporation vacuum coating machine provides high-efficiency PVD coating for stainless steel and metal components. It delivers superior adhesion, decorative finish, and customization options, making it ideal for sanitary ware, hardware, electronics, and decorative industries. ODM/OEM services are available. Contact us to inquire!

Technical Parameters:

| Target Materials | Al Wire, Cu, Ag, Cr (thermal), Decorative Metals |

| Coating Technology | Evaporation vacuum coating |

| Functional & Optical Films | Mainly for decorative coatings, it can be integrated with UV coating or spray layers. |

| Core Components | Arc target, control system, pump |

| Application | Plastics, daily ceramics, glass, jewelry & beads, stainless steel |

| Customization | Customized size, target material, color, fixture design, and process plan |

| Service | Mechanical/sample test reports, video outgoing-inspection, and technical guidance. |

Product Detail

Specifications of Evaporation Vacuum Coating Machine:

| Model Number | Dimension DxH (mm) | Ultimate Vacuum (Pa) | Pumping Time (Min) | Total Power (kW) |

| ZZ1214 | 1200*1400mm | ≤8×10⁻⁴ | <5 | 35 |

| ZZ1416 | 1400*1600mm | ≤8×10⁻⁴ | <5 | 65 |

| ZZ1618 | 1600*1800mm | ≤8×10⁻⁴ | <5 | 75 |

| ZZ1820 | 1800*2000mm | ≤8×10⁻⁴ | <5 | 90 |

| ZZ2020 | 2000*2000mm | ≤8×10⁻⁴ | <5 | 105 |

*Equipment specifications can be customized according to customer requirements.

Features of Evaporation Vacuum Coating Machine:

Advanced Evaporation PVD Technology: The PVD costing machine uses high-vacuum evaporation to deposit metal or alloy layers onto the workpiece surface. The process produces a dense, uniform coating with excellent adhesion. It supports multiple metals, including aluminum, chromium, titanium, and copper, to achieve various decorative effects.

Optimized for Stainless Steel and Metal Components: Designed specifically for stainless steel, aluminum, and copper alloy parts, ensuring even coating on complex surfaces. Ideal for industrial hardware, sanitary ware, and decorative metal products. Customizable trays and fixtures allow efficient batch production for different sizes and shapes.

Fully Automated and Intelligent Control: Equipped with PLC and HMI systems to precisely control temperature, vacuum, and evaporation rates. Memory function for production recipes ensures consistent coating quality across batches. Remote monitoring and error alarms simplify operation and reduce downtime.

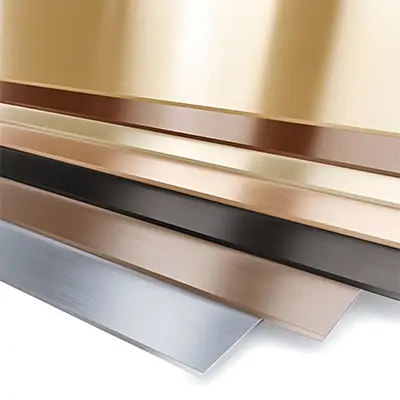

High Adhesion and Superior Decorative Finish: The PVD coating adheres tightly to metal surfaces, providing high gloss, mirror, matte, brushed, or gradient effects. Enhances corrosion and wear resistance, extending product lifespan. Meets export-quality standards and serves as an environmentally friendly alternative to traditional electroplating.

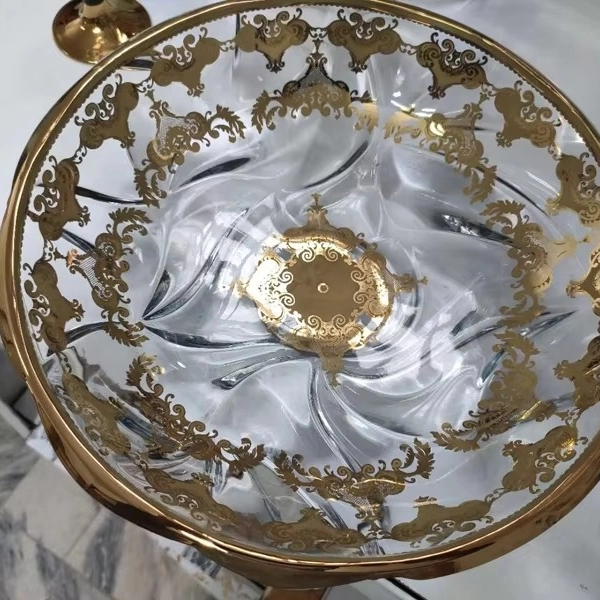

Wide Industrial Applications: Perfect for sanitary ware (faucets, shower heads, towel bars), kitchen and hotel hardware, consumer electronics, metal parts, ceramic and glass decoration, and jewelry or cosmetic packaging. Versatile enough for both decorative and functional coating requirements. Supports small batch and mass production efficiently.

Customizable Solutions: CGVAC offers full customization based on workpiece size, batch volume, coating color, and layer requirements. Can be upgraded to semi-automatic or fully automated multi-station systems for higher throughput. Supports multi-layer composite coatings to meet special visual or functional needs.

Custom Evaporation Vacuum Coating Machine

Why Choose CGVAC, Professional PVD Vacuum Coating Machine Manufacturer

High Production Efficiency

Excellent Film Quality

Intelligent Automation

IndepFull-System In-House R&D

Customization Support

Technical Service

Related Products

Contact Us

FAQ

- Q: What types of materials can PVD coating machines process?

A: Sanitary ware, jewelry &beads, daily ceramics, stainless steel, glass, plastics, and electronic & optical components for both decorative and functional coatings.

- Q: Can the CGVAC PVD vacuum coating machines be customized?

A: Yes. We offer standard and fully customized solutions, including chamber size, coating process, capacity, and color etc.

- Q: Do you provide installation and training?

A: Yes. We provide global on-site installation, operator training, and remote technical support.