Optical Vacuum Coating Machine with Multi-Arc Ion PVD Coating Technology

CGVAC optical vacuum coating machine with multi-arc ion PVD technology enables controlled film stress, high repeatability, and stable multi-layer deposition. CGVAC factory direct supply. Contact us for customized optical coating solutions and engineering support.

Technical Parameters:

| Target Materials | Titanium (Ti), Chromium (Cr), Zirconium (Zr), TiAl, Ni, Cu, Al, Fe, etc |

| Industrial gases | Argon (Ar), Nitrogen (N₂), Acetylene (C₂H₂), Oxygen (O₂) |

| Coating Technology | Multi-arc ion vacuum coating |

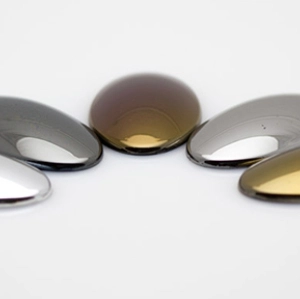

| Coating Color | Titanium silver, gold, rose gold, purple, sapphire blue, pearl, amber, deep gray, chrome black, and multicolor |

| Functional Coatings | TiN, TiCN, CrN, ZrN, TiAlN, CrAlN, DLC and other hard & wear-resistant coatings. |

| Core Components | Arc target, control system, pump |

| Application | Stainless steel, metal, sanitary ware, ceramic tableware, jewelry, glass, tile |

| Customization | Customized size, target material, color, fixture design, and process plan |

| Service | Mechanical/sample test reports, video outgoing-inspection, and technical guidance. |

Product Detail

Specifications of Optical Vacuum Coating Machine:

| Model Number | Dimension DxH (mm) | Ultimate Vacuum (Pa) | Pumping Time (Min) | Targets (PCS) | Total Power (KW) |

| DZ1214 | 1200*1400mm | ≤8×10⁻⁴ | <5 | 10 | 50 |

| DZ1416 | 1400*1600mm | ≤8×10⁻⁴ | <5 | 14 | 60 |

| DZ1618 | 1600*1800mm | ≤8×10⁻⁴ | <5 | 21 | 80 |

| DZ1818 | 1800*1800mm | ≤8×10⁻⁴ | <5 | 28 | 110 |

| DZ2118 | 2100x1800mm | ≤8×10⁻⁴ | <5 | 32 | 120 |

*Equipment specifications can be customized according to customer requirements. Height or depth can range from 600mm to 10000mm.

Features of the Optical Vacuum Coating Machine:

Optical-grade multi-arc ion deposition: Utilizing a highly stable multi-arc ion source, it provides a high-energy ion deposition environment, enabling the formation of dense, uniform thin film structures that meet the stringent quality requirements of optical coatings.

High coating consistency: It is achieved by independently adjusting the arc source, power supply, and bias parameters, which enables precise control over ion energy and deposition rate, thereby improving film thickness consistency and repeatability.

High-cleanliness vacuum chamber structure: CGVAC offers a dedicated optical vacuum chamber design, minimizing interference from particles and impurities to provide a stable and controllable deposition environment for optical films.

Multi-layer optical film system construction: Supports continuous deposition of multi-layer film structures, suitable for combinations of reinforcing films, protective films, and functional films, meeting diverse optical performance requirements.

Rotary clamping system: Multi-axis rotation and trajectory optimization design ensure stable film distribution for optical components during deposition, reducing edge and center deviations.

Multi-optical substrate compatibility: Adaptable to various substrates such as glass, optical crystals, and metal optical components, providing consistent coating performance for different optical products.

Multiple optical applications: The CGVAC optical vacuum coating machine is suitable for optical lenses and lens assemblies, optical decorative parts and protective films, optical functional surface treatment, and optical components for multiple industries, providing flexible and scalable overall solutions for optical coating in multiple fields.

Applications of Optical Vacuum Coating Machine

Why Choose CGVAC, Professional PVD Vacuum Coating Machine Manufacturer

High Production Efficiency

Excellent Film Quality

Intelligent Automation

IndepFull-System In-House R&D

Customization Support

Technical Service

Related Products

Contact Us

FAQ

- Q: What types of materials can PVD coating machines process?

A: Sanitary ware, jewelry &beads, daily ceramics, stainless steel, glass, plastics, and electronic & optical components for both decorative and functional coatings.

- Q: Can the CGVAC PVD vacuum coating machines be customized?

A: Yes. We offer standard and fully customized solutions, including chamber size, coating process, capacity, and color etc.

- Q: Do you provide installation and training?

A: Yes. We provide global on-site installation, operator training, and remote technical support.