If you’re choosing a surface treatment for an upcoming new product, one that’s durable, aesthetically pleasing, and meets customers’ expectations for a premium feel. You’ve probably already mentally listed three options: PVD coating, electroplating, and painting. Each method promises to give your product a “brand new” look, but in reality, their performance, lifespan, and suitable applications vary considerably. As a professional PVD coating machine manufacturer, CGVAC compares PVD vs electroplating vs painting, explaining how each technology works, its advantages and limitations, and why PVD coating is increasingly becoming the preferred choice for forward-thinking manufacturers.

Understanding Three Major Surface Finishing Technologies

PVD Vacuum Coating (Physical Vapor Deposition)

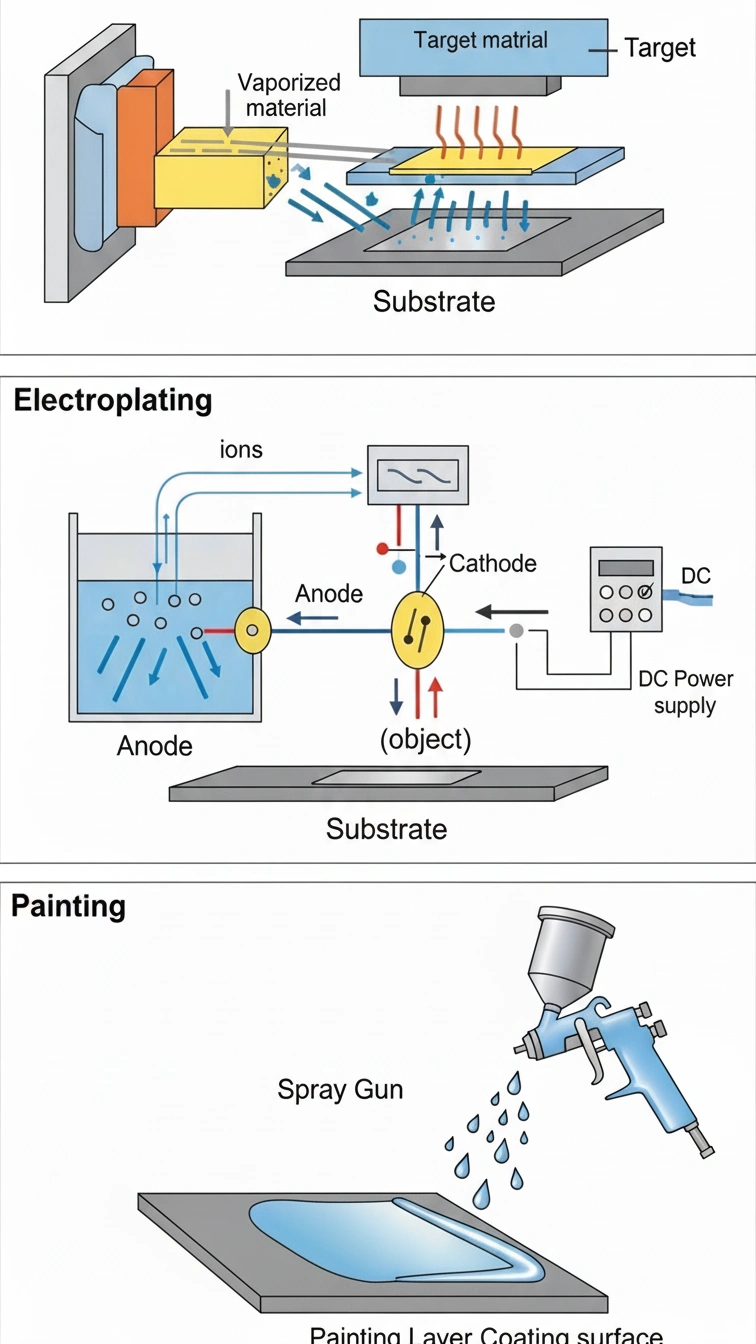

PVD Coating is a thin, dense, and highly adherent film deposited onto various materials as part of the physical process in a vacuum chamber. This involves the evaporation or sputtering of metals or ceramics into vapors, transportation in vacuums, and condensing on the product surface.

CGVAC provides four types of PVD coating equipment that can be engineered to suit any industrial need:

- Multi-Arc Ion Vacuum Coating Machine: high deposition rate, ideal for sanitary ware, plastics, jewelry.

- Magnetron Sputtering Vacuum Coating Machine: accurately controls film thickness, applied to stainless steel, sanitary ware, and decorative parts.

- Evaporation Vacuum Coating Machine: suitable for ceramics, electrical components, and smooth decorative finishes.

- Functional PVD Coating Machine: allows for anti-fingerprint, anti-reflective, wear-resistant, or optical functional films.

PVD technology is widely applied to sanitary ware, stainless steel products, jewelry & beads, daily-use ceramics, glass products, plastic components, and electronics.

Electroplating

Electroplating is an electrochemical process whereby a deposit of metal from solution onto the product surface is achieved. It is widely used due to its relatively low initial cost and fast production speeds. However, electroplating requires chemical baths containing heavy metals and generates environmentally hazardous wastewater. Adhesion and corrosion resistance are usually weaker than PVD coatings.

Painting (Spray Coating)

Painting involves atomized liquid coating applied to the product surface, mainly for color decoration. It is flexible and low-cost, commonly used for plastics, household utensils, furniture, and consumer goods. Paint coatings generally have the lowest durability, prone to peeling, scratching, or fading, and VOC emissions make it less eco-friendly.

Performance Comparison: PVD vs Electroplating vs Painting

| Feature | PVD Coating | Electroplating | Painting / Spray Coating |

|---|---|---|---|

| Adhesion & Durability | High – strong molecular bonding, excellent scratch and wear resistance | Moderate – can peel or corrode over time | Low – prone to scratches, peeling, and abrasion |

| Aesthetic & Color Consistency | Premium metallic colors (gold, rose gold, black, rainbow), uniform finish | Limited metallic colors, less consistent | Rich color options but weak metallic or glossy effect |

| Environmental Impact | Eco-friendly, chemical-free, meets global environmental standards | Generates heavy-metal wastewater, requires strict compliance | VOC emissions, requires ventilation and odor control |

| Cost & Efficiency | Higher initial investment, low long-term operational cost, low rejection rate | Low initial cost, increasing compliance costs | Low equipment cost, frequent rework increases total cost |

| Film Thickness & Uniformity | Thin, uniform, controllable, even on complex shapes | Thicker but less uniform, risk of uneven deposition | Variable thickness, operator-dependent, less consistent |

Why More Manufacturers Choose PVD Coating?

PVD coating is not only a decorative solution but also a transformative surface-enhancement technology. Key advantages include:

Superior Film Quality

PVD coatings offer excellent hardness, corrosion resistance, and color consistency, ideal for high-end products requiring stable quality.

Meets Global Environmental Regulations

PVD is eco-friendly, chemical-free, and compliant with international environmental standards. Factories using PVD vacuum coating equipment gain competitive advantages when exporting to Europe, North America, and Southeast Asia.

Supports Future Manufacturing Trends

Industries like sanitary ware, jewelry, electronics, and home hardware are transitioning from traditional plating to vacuum coating technologies. Early adoption positions manufacturers for high-value markets.

Compatible with Multiple Materials

From sanitary ware, jewelry, stainless steel, ceramics, glass, plastics, to electronics, PVD coatings provide higher performance and more attractive finishes than electroplating or painting.

Aligns with Industrial Automation and Cost Control

CGVAC PVD coating machines are engineered for stable, continuous, and automated production—reducing labor costs and improving yield rates.

Why Choose CGVAC as Your PVD Coating Machine Manufacturer?

As a professional PVD coating machine manufacturer, we help global customers achieve precise coating results and efficient factory-level deployment.

- Full series of PVD thin film deposition equipment: multi-arc, magnetron sputtering, evaporation, and functional coating machines

- Expertise in coating stainless steel, sanitary ware, jewelry, ceramics, glass, and electronics

- Customized PVD coating solutions tailored to production scale, target colors, decrocative and functional requirements

- Global installation, operation training, and after-sales support

- Reliable industrial equipment built for stable long-term operation

CGVAC helps manufacturers upgrade from traditional electroplating and painting to modern, eco-friendly, high-performance PVD coating solutions.

Conclusion

PVD coating, electroplating, and painting each serve different needs, but PVD vacuum coating has become the most advanced, durable, and environmentally sustainable choice for global manufacturers. With CGVAC’s full range of PVD coating machines, companies can enhance product performance, elevate appearance, and strengthen competitiveness in global markets. If you are planning to upgrade your surface finishing technology or explore PVD coating for your production lines, contact us today for customized PVD coating machine solutions and a professional quotation.